Design and production

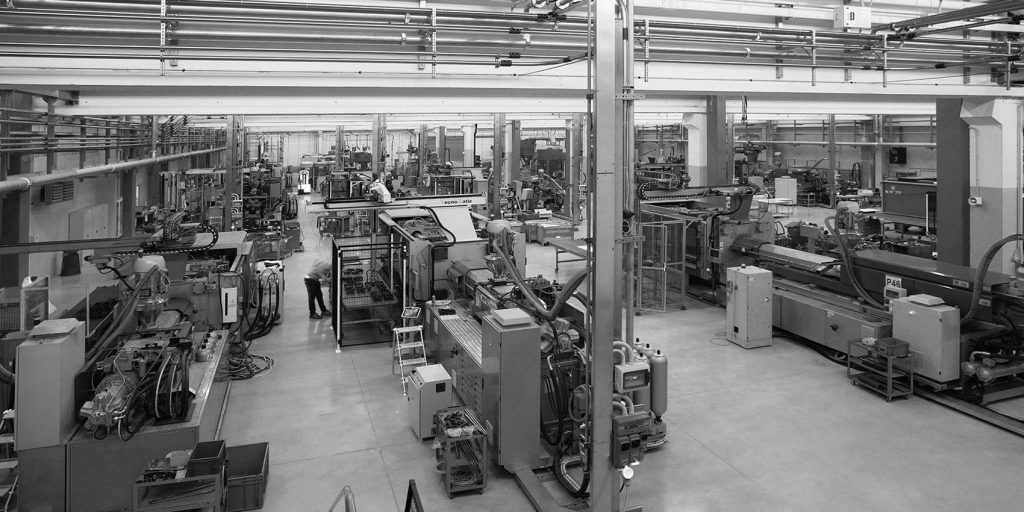

Since our foundation, we’ve been delivering tailored solutions to Customers all over the world, from project development to industrialization till final delivery.

Our philosophy is to approach every project together with Customers and work closely with them to ensure that desired specifications are met. Our team has a broad experienced in co-designing, material selection and industrial processes to fulfill customer’s expectations in terms of quality and costs.

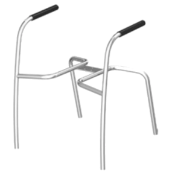

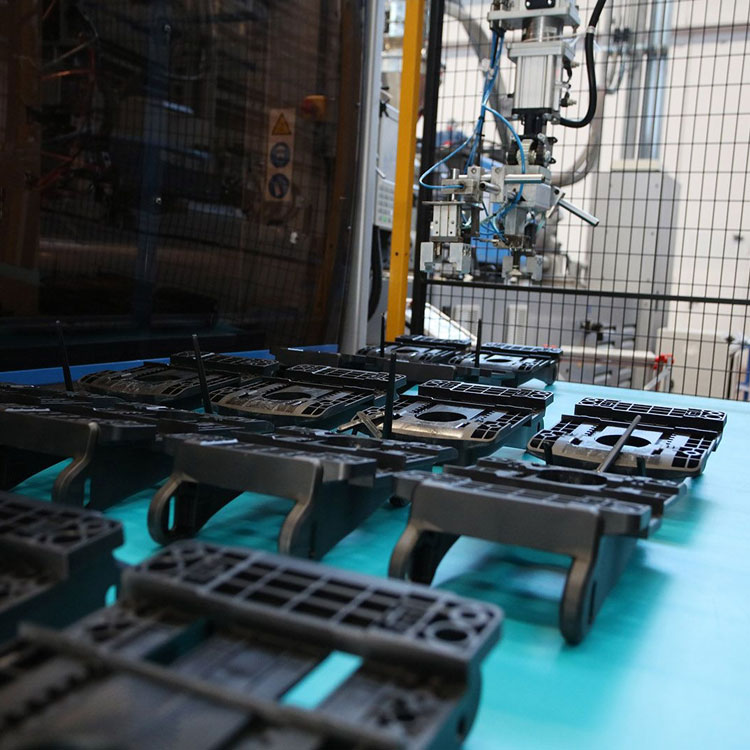

Customers can rely on our certified processes and advanced technologies, which allow us to achieve excellent results in the fabrication of steel frames: production assets include multiple pipe and wire bending machines, welding robots, state-of-the-art galvanic finishing plant, automated polishings and a powder painting shop, just to name a few.

The prototype and quality departments take advantage of laser and optical scanners, dynamometers, durometers and spectrophotometers for reverse engineering or dimensional check; while the internal laboratories, with CATAS machineries, allow us to perform tests to guarantee the compliance of the products with regulations and certify their maximum reliability and extended life.

In order to provide customers with the highest level of service, we define the production plan using AI algorithms, while our digitalized warehouses and logistics systems ensure that products are delivered to clients on time and properly packed.

At IMARC Industries we are proud of our ability to deliver exceptional services and products to our clients. We believe that our extensive experience and expertise in the field make us the ideal partner for any design company looking for high-quality technical components and steel frames.